Benzyl Glycidyl Ether:Application and Chemistry Studies

General Description

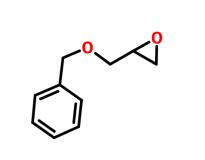

The Benzyl Glycidyl Ether, with the CAS No:2930-05-4, belongs to the aryl glycidyl(oxiran-2ylmethyl) ethers. Its chemical’s molecular formula is C10H12O2 and molecular weight is 164.201. It is a colorless and transparent liquid with low odor, low toxicity, low volatility and good chemical stability. It is often used as an epoxy reactive diluent to reduce the viscosity of epoxy resins. Used in electronics, electrical appliances, electromechanical, mechanical, construction, coatings and adhesives. Compared with butyl glycidyl ether, the structure of benzyl glycidyl ether contains rigid segments, and the heat distortion temperature of the cured product is significantly increased.[1] The previous studies also showed The Benzyl Glycidyl Ether and their diols are useful intermediates for synthesis of chirally relevant compounds in pharmaceutical, agrochemical and fine chemical industries.[2]Optically pure Benzyl glycidyl ether is an important precursor for the synthesis of many drugs and natural products.[3]

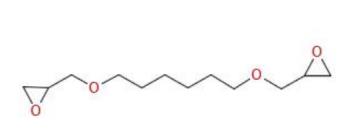

Figure 1 the molecular formula of the Benzyl glycidyl ether

Application

Benzyl glycidyl ether, an aromatic compound, is an inexpensive and commercial epoxy reactive diluent. The addition of Benzyl glycidyl ether to epoxy can reduce the viscosity, increase the fluidity and improve the processability.[4] In addition, Pandini et al. mentioned in their research that the addition of monofunctional epoxy monomer like BGE also increased the modulus and strength of cured epoxy resin products at room temperature according to the phenomenology of the so called “internal antiplasticization”.[5] Inspired by this conclusion, researchers prepared a sustainable graphene dispersion in this work using Benzyl glycidyl ether as a dispersant since the benzene ring has been reported to have reliable affinity with graphene via π-π interactions , as shown in Scheme1.[6-7]Then the graphene dispersion was used to manufacture graphene/epoxy nano composites and the mechanical properties, thermomechanical performances, thermal stability, and thermal conductivity were investigated. It is noteworthy that graphene and Benzyl glycidyl ether can simultaneously improve the tensile strength and modulus of epoxy matrix. Therefore, Benzyl glycidyl ether has multiple functions in this nanocomposite: (1) the epoxy group of Benzyl glycidyl ether reacts with the curing agent to participate in the formation of the network and reinforce epoxy matrix via “internal antiplasticization”;(2) Benzyl glycidyl ether improves the dispersity of graphene in epoxy resin; (3) Benzyl glycidyl ether acts as a connection to enhance interfacial bonding between graphene and matrix with the help of Benzyl glycidyl ether dispersion function and the participation of Benzyl glycidyl ether in the formation of the host epoxy curing network; (4) Benzyl glycidyl ether can reduce system viscosity and optimize the processability.[3]

There are research results showedusing commercial Benzyl glycidyl ether as a dispersant and surface modifier of graphene, has the advantages of simplicity and scalability. Benzyl glycidyl ether plays multiple roles in the graphene/epoxy nanocomposites. First, Benzyl glycidyl ether can enhance the host epoxy, which has been demonstrated by significant increase in strength and modulus. In addition, Benzyl glycidyl ether promotes uniform dispersion of graphene in the matrix and the interaction between graphene and matrix through π-π interaction. The π-π interaction between Benzyl glycidyl ether and graphene was demonstrated by dispersion durability experiments, UV spectroscopy, and Raman spectroscopy. After systematic analysis with tensile test and DMA, it can be deduced that, on the basis of Benzyl glycidyl ether enhancement, small amount of graphene has a significant enhancement to the host epoxy. This dual enhancement methodology may provide a feasible way to fabricate high-performance graphene polymer nanocomposites in engineering applications.[3]

Preparation

Biosynthesis: The typical procedure for preparing Benzyl glycidyl ether reinforced epoxy resin was as follows: Host epoxy DER-332 was mixed with Benzyl glycidyl ether (molar fractions of Benzyl glycidyl ether in host epoxy were 5%, 10%, 20% and 40%, respectively). Subsequently, the stoichiometric ratio of DDM was added, and followed by stirring for 15min till homogeneous mixture was obtained. Then the samples were degassed in a vacuum oven at 80℃ for 10min. Finally, all the blends were poured into the mold and cured at 100℃ for 2h, 120℃ for 2h and 150℃ for 4h. According to the molar fractions of Benzyl glycidyl ether in host epoxy increased from 5%, 10%, 20% to 40%, the obtained samples were named as EPþ5%Benzyl glycidyl ether, EPþ10%Benzyl glycidyl ether, EPþ20%Benzyl glycidyl ether, and EPþ40% Benzyl glycidyl ether, respectively. The sample without Benzyl glycidyl ether was referred to as EP.[3]

Chemistry Synthesis:To a stirred mixture of epichlorohydrin (2.0g, 21.6mmol), benzyl alcohol (2.12g, 19.6mmol) and tetrabutylammonium hydrogen sulphate (290mg, 0.86mmol) were added to 50% (w/v) aqueous NaOH (10ml) drop wise at 0°C and the reaction mixture was allowed to stir for 30 min at the same temperature. The stirring was continued for additional 4h after which the mixture was extracted with diethyl ether. The ether-extract was washed with brine (2×10ml), dried over anhydrous sodium sulfate and evaporated under reduced pressure. The residue was purified by column chromatography on silica gel using a mixture of hexane: ether (6:1) as eluent to obtain an overall yield of 2.0g (65%). The parameter supporting the best yield and enantiomeric excess of benzylglycidyl ether in the respective experiments were used in further studies. Benzyl glycidyl ether does not undergo auto-hydrolysis observed by researchers in light of their all optimization experiments. The epoxide was added to the bacterial cell grown for varying period of time to analyze the effect of age of bacterial cells on the bio-transformation and enantiomeric excess of the synthesized compound (Benzyl glycidyl ether). The addition of substrate to cells during stationary phase afforded best transformation efficiency, yielding Benzyl glycidyl ether with an ee of 8% and 3-(benzyloxy) propan-1,2-diol with an ee of 42%.[8]

Reference

[1]Hou J,Sun X, Sun T, et al.Preparation of benzyl glycidyl ether. Faming Zhuanli Shenqing (2022), 8pp.

[2]Bendigiri C, Harini K, et al. Evaluating Ylehd, a recombinant epoxide hydrolase from Yarrowia lipolytica as a potential biocatalyst for the resolution of benzyl glycidyl ether[J]. Rsc Advances, 2018, 8(23):12918-12926.

[3]Jin H, Li Y, Zhang Q, et al. Enantioselective Hydrolysis of Styrene Oxide and Benzyl Glycidyl Ether by a Variant of Epoxide Hydrolase from Agromyces mediolanus.[J]. MDPI AG, 2019(6).

[4]Duan W, Chen Y, Ma J, et al. High-performance graphene reinforced epoxy nanocomposites using benzyl glycidyl ether as a dispersant and surface modifier[J]. Composites Part B: Engineering, 189.

[5]Pandini S, Bignotti F, Baldi F, et al.Thermomechanical and large deformation behaviors of antiplasticized epoxy resins: effect of material formulation and network architecture[J]. Polym Eng Sci 2017, 57(6).

[6]Shen B, Zhai W, Chen C, et al. Melt blending in situ enhances the interaction between polystyrene and graphene through π-π stacking[J]. ACS Appl Mater Interfaces. 2011, 3(8):3103.

[7]Cao L, Liu X, Na H, et al. How a bio-based epoxy monomer enhanced the properties of diglycidyl ether of bisphenol A (DGEBA)/graphene composites[J]. J Mater Chem 2013, 1(16):5081–8.

[8]Neeraj Bala, Kirandeep Kaur, et al. Bioresolution of benzyl glycidyl ether using whole cells of Bacillus alcalophilus[J]. Journal of Basic Microbiology. 2012.

);Related articles And Qustion

See also

Lastest Price from BENZYL GLYCIDYL ETHER manufacturers

US $10.00/kg2024-04-23

- CAS:

- 89616-40-0

- Min. Order:

- 1kg

- Purity:

- 99.6%

- Supply Ability:

- 100000

US $1000.00/kgkg2023-12-11

- CAS:

- 89616-40-0

- Min. Order:

- 1kgkg

- Purity:

- 0.99

- Supply Ability:

- 100