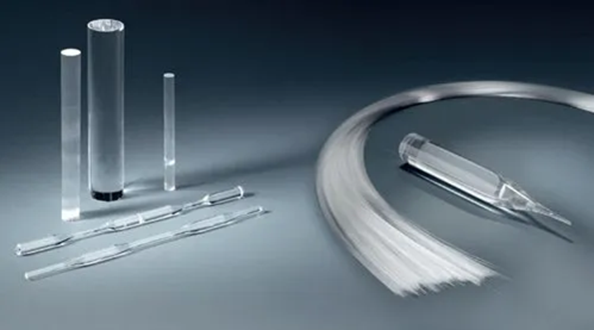

Vitreous or Amorphous Silica

Introduction

High-purity amorphous or fused silica, also called vitreous silica, when optically translucent is a high-performance ceramic obtained by electrothermal fusion of high-grade silica sand with a silica content above 99.5 wt.% SiO2 into an AC electric-arc furnace (EAF) at a temperature of around 1800 to 2100°C. The melt is then rapidly quenched to prevent crystallization.

Fused silica has a mass density of 2200 kg.m–3 while vitreous silica is slightly denser with a density of 2210 kg.m–3. Mechanically, fused silica is a relatively strong but brittle material with a tensile strength of 28 MPa, a compressive strength of 1450 MPa, and a Mohs hardness of 5. Both grades exhibit an extremely low coefficient of thermal expansion (e.g., 0.6 × 10–6 K–1from 20 to 1000°C) and a remarkable thermal shock resistance together with a low thermal conductivity. Fused silica, with a dielectric field strength of 16 MV.m–1, exhibits also excellent electrical insulation capabilities up to 1000°C. When heated above 1150°C, fused silica converts irreversibly into α-cristoballite as follows:

fused silica —> α-cristoballite (1150°C)

Application

Fused silica begins to soften at 1670°C and melt at 1755°C. From a chemical point of view, fused silica possesses an excellent corrosion resistance to most chemicals, especially strong mineral acids, molten metals, and molten glasses.

Common industrial uses for fused silica are steelmaking, coke making, metallurgy, glass production, nonferrous foundries, precision foundries, ceramics, the chemical industry, the nuclear industry, and finally aeronautics.

);You may like

See also

Lastest Price from Silica glass manufacturers

US $0.00/kg2023-09-14

- CAS:

- 60676-86-0

- Min. Order:

- 1kg

- Purity:

- 99.99%

- Supply Ability:

- 20tons